About this mod

A substantial overhaul for the SH282 from the tender to smokebox with improvements to realism and hauling power. Includes a steam-powered mechanical stoker.

- Requirements

- Permissions and credits

- Changelogs

Quick Start

- Open the damper by pulling it up.

- Add 1 or 2 shovelfuls of coal to the firebox and light the fire.

- Set the reverser to full forward or back.

- Slowly open the regulator until the locomotive starts moving.

- At about 10 kph, reduce reverser to 1/2 and open the regulator.

- At about 20 kph, reduce reverser to 1/4 and open the regulator to full.

- You may now control acceleration by adjusting the reserver.

Tips

- Adjustments to the regulator, reverser, and blower will have a large effect on firebox temperature and steam generation rate. Reverser settings below 1/4 will generally not generate enough steam to maintain pressure.

- Do not add too much coal to the firebox! If the smoke from the chimney is dark black, turn on the blower until the temperature gauge stops rising.

- If blower is fully opened and smoke is still black, dump coal from the firebox by holding opening the Fire Out valve.

- Opening the injector too far will rapidly reduce steam pressure. It is best to refill the boiler when coasting after a hard climb, to avoid losing steam pressure through the safety valves.

- When coasting with the injector closed, closing the damper by pushing it down will reduce coal consumption and steam generation, preventing loss of steam through the safety valves. Don't forget to open the damper again before opening the regulator!

Background

What is cutoff?

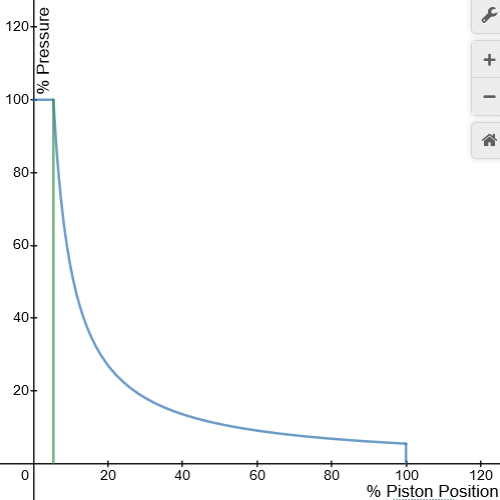

Cutoff is the point at which the intake valve closes, preventing more steam from traveling from boiler into the cylinder. Before the cutoff point, the steam in the cylinder is nearly full boiler pressure. After the cutoff point, no further steam enters the cylinder, and the pressure drops as the piston moves. However, the steam already in the cylinder continues to push against the piston, giving "free" energy. This is called "expansive working," and is key to efficient operation of a steam engine.

If we lengthen the cutoff, the valve closes later, more steam travels from the boiler to the cylinder, and cylinder pressure remains high for a longer time.

(Click here for an interactive version of this graph)

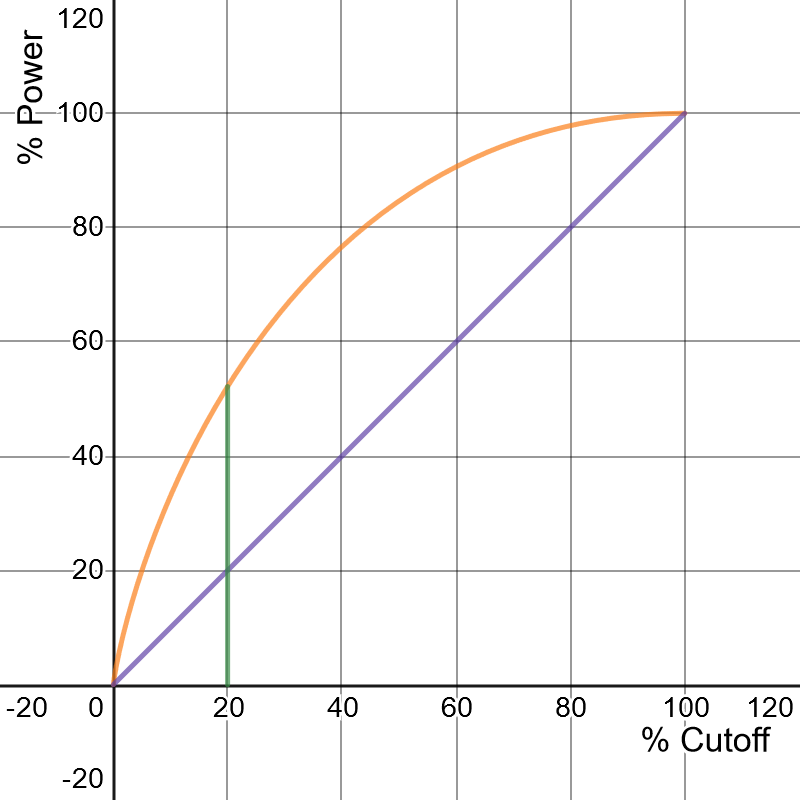

The work done by the steam on the piston is the area under the curve. Let's see how the work done, and consequently the power output of the steam engine, changes with the length of the cutoff:

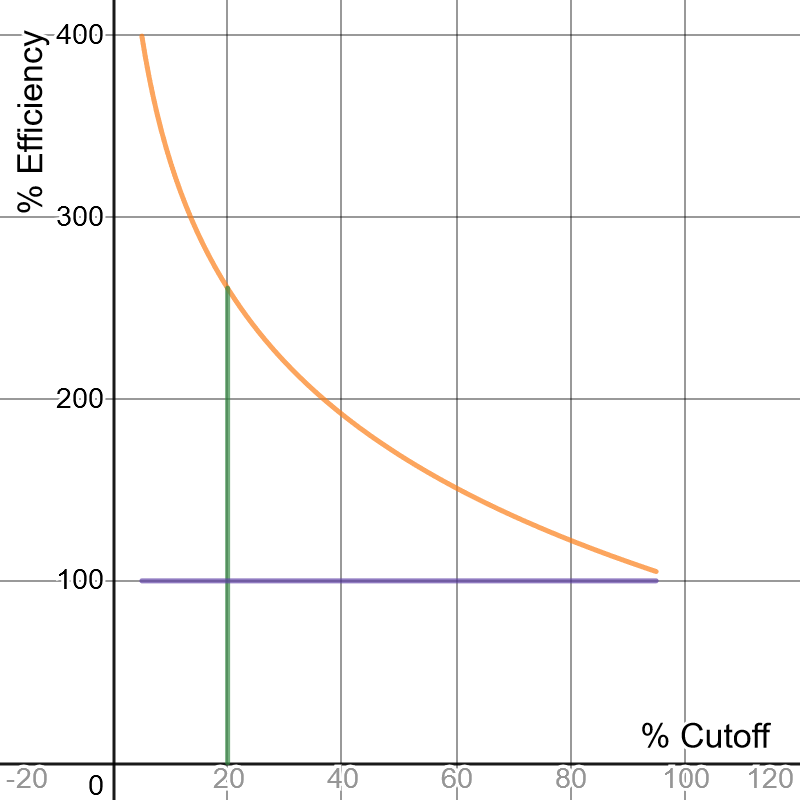

The lower line shows how much steam is admitted to the cylinder, and the upper shows the total work done by that steam. The distance between the two lines is the amount of "free" energy obtained through expansive working. If we normalize this graph by the amount of steam consumed we see the effect of cutoff on efficiency:

At a cutoff setting of 20%, we get 2.6 times as much work from the same amount of steam as we would at 100% cutoff, and lower cutoff settings are even better!

What about the throttle?

The effect of the throttle is to limit the pressure sent to the cylinders. Since the graphs are all normalized to 100% being the input pressure, changing the throttle scales the pressure and power graphs vertically, but leaves the efficiency unchanged since that is already normalized by steam consumption.

(Click here for an animated graph of the effect of the throttle)

About This Mod

In vanilla Derail Valley, the SH282 behaves oddly and unrealistically: There is a different cutoff wheel position for optimum power that depends on the locomotive's speed, but the cutoff wheel has no effect on engine efficiency. Steam consumption is influenced only by torque output, even if the locomotive is not moving, and no steam is theoretically being admitted into or ejected from the cylinders.

Realistic Steam Cutoff makes several changes to the behavior of the SH282 steam locomotive in Derail Valley.

- Realistic cutoff setting modelling, inline with the theory described above. Longer cutoff (further from center) always gives more power, and shorter cutoff (closer to the center) gives better efficiency.

- Steam consumption is proportional to locomotive speed. More speed = more piston strokes = more steam required.

- Boiler steam production and maximum pressure is substantially reduced.

In combination, this has some very noticeable effects on how the steamer performs:

- You will spend most of your time underway at very low cutoff settings, 15% or less, just as in reality.

- As long as you have the traction necessary to move the train, you can climb grades of virtually any length without running out of steam. The SH282 is capable of moving massive loads up grades, albeit slowly. Managing your sand is vital, and be careful not to lose steam through the safety valve!

- The boiler has significant trouble maintaining pressure when sustaining high-speeds of 80+ kph. Just as in reality, this is the most demanding situation for a boiler's power output. Historically, the desire for higher train speeds is what drove railroads to seek larger fireboxes and greater steam generating capacity.

- It is viable to use the SH282 as an efficient shunter, or even as a quasi-fireless locomotive, operating at low speeds and high tractive effort from steam pressure in the boiler.

Mechanical Stoker

The unlabeled valve to the right of the Steam Dump valve controls the amount of steam sent to the mechanical stoker. When opened, the stoker will steadily move coal from the tender into the firebox. Be careful: too much coal in the firebox will require more oxygen to burn quickly than the chimney can draw at low speed, smothering the fire and reducing the amount of heat generated.

The Fire and You

The fire requires large amounts of oxygen to burn efficiently. Complete combustion of coal yields 4x the energy and thus steam as coal burned incompletely. You can judge the state of the fire by looking at the color of the smoke emitted from the chimney. An efficient fire gives off nearly transparent smoke seen mostly as a haze above the chimney. A poorly burning fire gives off dense, dark black smoke.

The main factor affecting how much air the fire gets is the amount of steam consumed by the cylinders and ejected from the chimney. The movement of the exhaust steam creates a partial vacuum in the smokebox (draft) which pulls air from the outside world through the firebox. Thus steam generation is partially self-regulating: the more you use, the more heat and steam is generated. Running the steam engine too efficiently, by using a very low cutoff, can mean not enough draft is present to regenerate the steam consumed from the boiler. A setting of approximately 10% is the most sustainable cutoff setting.

If you need a hot fire at low speeds, such as when first pressurizing an empty boiler, or recovering from a stall on a hill, you can waste steam by sending it up the chimney to boost draft. This is the "blower." If the fire is burning well with clear smoke, increasing the steam sent to the blower will not help the fire burn hotter.

You can control the amount of air going to the fire through the damper lever. Pulling the handle up opens the damper, while pushing it down closes the damper. Closing the damper will restrict air to the fire, causing it to burn inefficiently, but also greatly reducing how fast the coal burns. If you have too much steam, such as when going downhill or stopping at a station, closing the damper will prevent coal and steam from being wasted out of the safety valves. The damper starts out closed. You must open it before starting the fire to generate steam.

Contributions and bug reports are welcome on Github.

DO NOT REPORT BUGS TO THE DEVELOPERS IF YOU ARE RUNNING MODS.

Source Code